Camp Reboot in Palemo, Maine is 1,100 feet and designed by GO Logic.

Copyright 2017 Josh Gerritsen Media

I have been in awe of the houses designed by GO Logic fo several years and have included their homes in several of my books. They have been innovators in designing and building prefabricated houses as well as extremely energy efficient ones – many Passive House certified. When I heard that Matthew O’Malia, G O Logic co-founder and principal architect was starting a new insulation company I was excited to hear about it, since Matthew has always been at the cutting edge of highly efficient home design. I posed some questions to Matthew and here are his responses.

How did your training in Germany influence your design approach as an architect?

My work experience and postgraduate studies in conceptual design in Frankfurt opened my eyes to the real bedrock of sustainable construction: thoughtful systems working together to create built environments requiring little operational input. While still in Europe, I began thinking about how, as an architect, I could apply this broader, long-term vision of efficiency to construction in the United States.

The start of this endeavor really came to life in 2008 when Alan Gibson and I founded GO Logic on the coast of Maine, where we began designing and constructing buildings using Passive House standards to guide us. We found great success incorporating continuous insulation, air sealing, high-performance windows and doors to create building envelopes calling for very small heating and cooling loads.

We designed and built the first Passive House in Maine and expanded our reach throughout New England and beyond.

The Cousins River Residence, designed by GO Logic is in Freeport Maine and is 1600 square feet.

Photo courtesy of trentbellphotography

How does a Passive House architect become the co-founder of GO Lab, Inc., a company set to manufacture wood fiber insulation?

Through my experience at GO Logic, I came to realize insulation is so much more than just R-value. Our builders complained of the itchy particles from mineral wool and fiberglass, and they voiced concerns about air quality. Our jobsites produced non-recyclable scraps of foam that took up tremendous space in the dumpster; foam microbeads and plastic dust from cutting board insulation always covered the ground and the installers’ clothes during and after application.

MORE FOR YOU

And I grew more concerned about an ideological contradiction: We were using insulation products heavily derived from or reliant on fossil fuels to reduce the amount of fossil fuel required to operate the buildings we were designing. We were reducing operational energy, but canceling that out by using insulations that were high in embodied carbon. It seemed like a zero-sum game, or worse, when it came to looking at the environmental impact associated with construction. I began looking for other solutions.

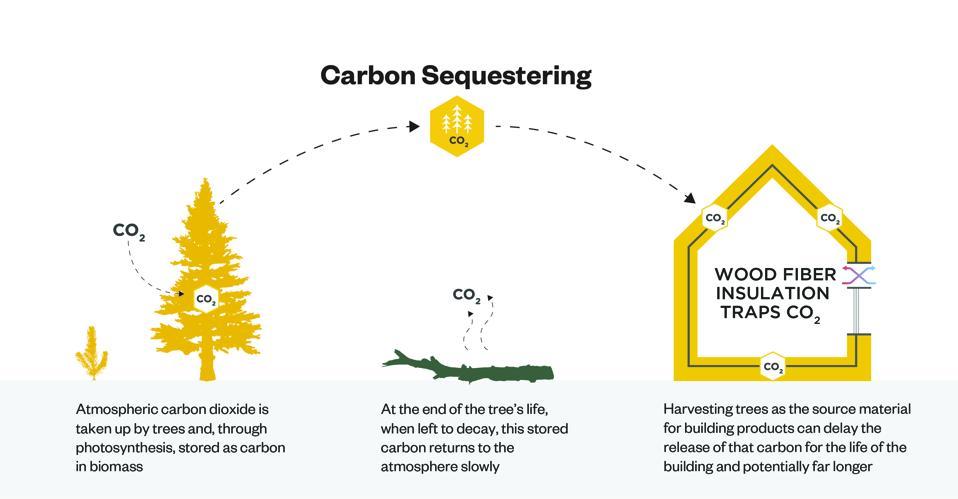

Leveraging wood fiber insulation to address today’s climate concerns by sequestering carbon.

Graphic courtesy of GO Lab

In 2016, I partnered with Josh Henry, current GO Lab President. Josh holds a PhD in Physical Chemistry and Materials Science and has a deep background in advancing renewable energy and energy conservation technologies. Together, we discovered that wood fiber insulation offered the high performance we desired, while checking all the other boxes on our list.

The biggest problem with wood fiber insulation was we couldn’t get it without paying a significant premium to cover freight costs from Europe. There are 15 manufacturing plants across Europe supporting $700M in sales across the EU, but there is currently no manufacturer of wood fiber loose fill, batt, or dry-process board in North America.

Josh and I began asking, “Why isn’t someone manufacturing wood fiber insulation domestically?” As we searched for the answer, we learned that the entire product line could be produced more affordably here than in Europe due to much lower raw material and energy costs.

I remember thinking, “Imagine the impact of being able to provide the mainstream construction market an affordable, high-performance insulation product line not derived from or highly dependent on fossil fuels. Imagine the potential for carbon sequestration in the U.S. housing market alone.”

So we set out to manufacture wood fiber insulation for the first time in North America starting in 2022.

How do you see mainstream construction in the U.S. accepting wood fiber insulation?

Wood fiber insulation has so many layers of benefit, so many stories to tell. We knew we needed to find a good strategy to package all the messages for a broad audience. We decided to leverage our brand name, TimberHP, to deliver the themes that resonate so loudly around wood fiber insulation. Timber clearly defines where our product starts: the vast forestlands of Maine. HP has three layers: High Performance; Healthy People; Healthy Planet.

High Performance—Fortunately for us, European manufacturers, designers, and building scientists have perfected wood fiber insulation systems through two decades of application and innovation.

Healthy People—With no toxins, harmful particles, and wood fiber’s ability to manage humidity; we have quite a story to tell about safe installation and improved indoor air quality.

Healthy Planet—The carbon impact is the biggest story to tell here.

Impact investing continues to be an area drawing a lot of attention. Can wood fiber insulation remove carbon from the atmosphere at the level of scale that can attract significant impact investment?

There is no doubt in my mind that we can make that case. Wood fiber insulation is unique. It’s made from trees and ends up storing the original carbon that was locked away, sequestered if you will, in those original trees. Wood fiber insulation also inhibits heat loss, meaning it saves operational energy, whenever and wherever it’s installed.

There is a massive amount of existing housing stock that is either entirely uninsulated or in need of serious renovation. As a market opportunity and a carbon mitigation opportunity, it’s absolutely huge! Just retrofitting 10% of the existing housing stock in the U.S. to code-plus levels, would sequester half a gigaton of carbon alone. And that’s just the embedded carbon, not the operational carbon it will save long into the future as well.

There’s no new science here. There’s no battery that has to be vetted. Everyone knows how to do it. We need to have the will to do it. And if we have the will to install and replace insulation, at scale, with wood fiber; we will make immediate progress on today’s problem.